OEM manufacturer Cold Rolled Steel Sheets - COLD WORK STEEL – Histar

OEM manufacturer Cold Rolled Steel Sheets - COLD WORK STEEL – Histar Detail:

Mainly Cold Work Steel Grade No. We Supplied:

| HISTAR |

DIN |

ASTM |

JIS |

| HSC 2 | 1.2379 | D2 | SKD11 |

| HSC3 | 1.2083 | D3 | SKD1 |

| HSC1 | 1.2510 | O1 | SKS93 |

| HSC7 | |||

| HSC8 | Bohler K340 | ||

| HSC9 | 1.2327 | Bohler K310 | |

| C28 | 1.2631 | A8 Mod. | |

| HSC50 | 1.2550 | S1 |

Size:

| HISTAR |

DIN |

ASTM |

CHEMICAL COMPOSITION |

PROPERTY |

APPLICATION |

||||||||

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

V |

W |

|||||

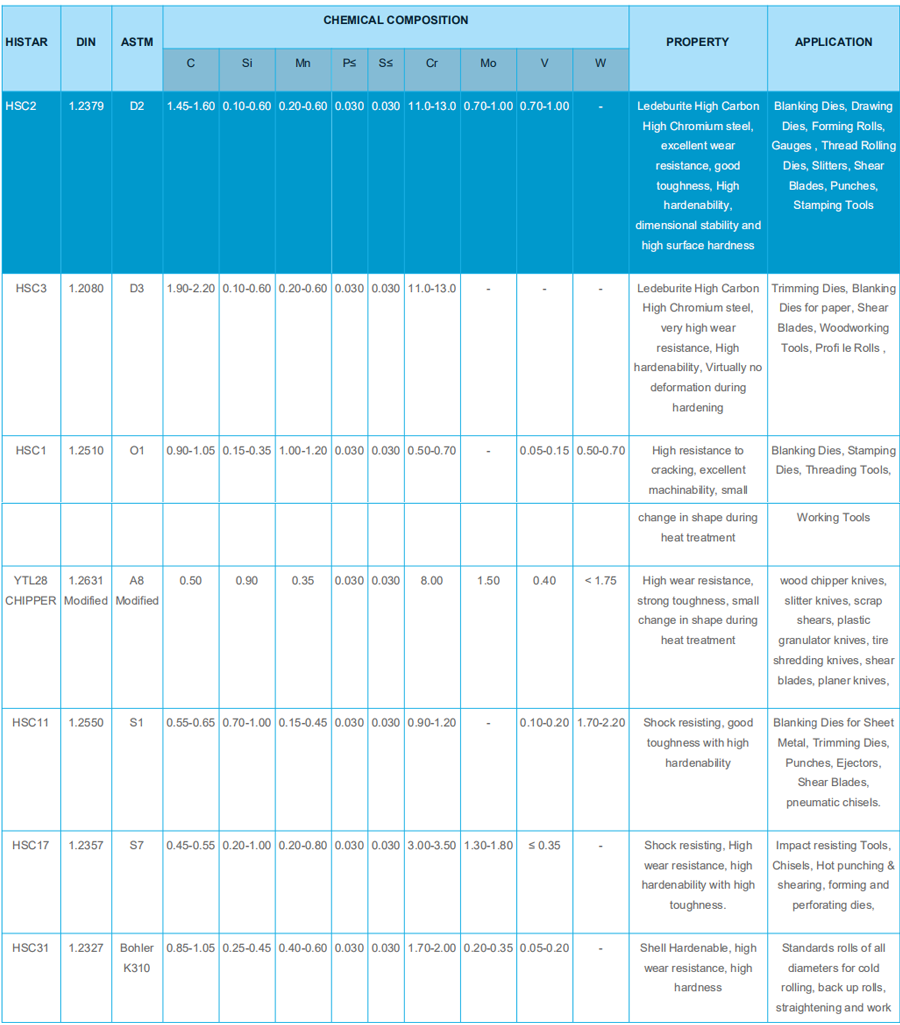

| HSC2 |

1.2379 |

D2 |

1.45-1.60 |

0.10-0.60 |

0.20-0.60 |

0.030 |

0.030 |

11.0-13.0 |

0.70-1.00 |

0.70-1.00 |

- |

Ledeburite High Carbon High Chromium steel, excellent wear resistance, good toughness, High hardenability, dimensional stability and high surface hardness |

Blanking Dies, Drawing Dies, Forming Rolls, Gauges , Thread Rolling Dies, Slitters, Shear Blades, Punches, Stamping Tools |

|

HSC3 |

1.2080 |

D3 |

1.90-2.20 |

0.10-0.60 |

0.20-0.60 |

0.030 |

0.030 |

11.0-13.0 |

- |

- |

- |

Ledeburite High Carbon High Chromium steel, very high wear resistance, High hardenability, Virtually no deformation during hardening |

Trimming Dies, Blanking Dies for paper, Shear Blades, Woodworking Tools, Profi le Rolls , |

|

HSC1 |

1.2510 |

O1 |

0.90-1.05 |

0.15-0.35 |

1.00-1.20 |

0.030 |

0.030 |

0.50-0.70 |

- |

0.05-0.15 |

0.50-0.70 |

High resistance to cracking, excellent machinability, small change in shape during heat treatment |

Blanking Dies, Stamping Dies, Threading Tools, Working Tools |

|

YTL28 CHIPPER |

1.2631 Modified |

A8 Modified |

0.50 |

0.90 |

0.35 |

0.030 |

0.030 |

8.00 |

1.50 |

0.40 |

< 1.75 |

High wear resistance, strong toughness, small change in shape during heat treatment |

wood chipper knives, slitter knives, scrap shears, plastic granulator knives, tire shredding knives, shear blades, planer knives, |

|

HSC11 |

1.2550 |

S1 |

0.55-0.65 |

0.70-1.00 |

0.15-0.45 |

0.030 |

0.030 |

0.90-1.20 |

- |

0.10-0.20 |

1.70-2.20 |

Shock resisting, good toughness with high hardenability |

Blanking Dies for Sheet Metal, Trimming Dies, Punches, Ejectors, Shear Blades, pneumatic chisels. |

|

HSC17 |

1.2357 |

S7 |

0.45-0.55 |

0.20-1.00 |

0.20-0.80 |

0.030 |

0.030 |

3.00-3.50 |

1.30-1.80 |

≤ 0.35 |

- |

Shock resisting, High wear resistance, high hardenability with high toughness. |

Impact resisting Tools, Chisels, Hot punching & shearing, forming and perforating dies, |

|

HSC31 |

1.2327 |

Bohler K310 |

0.85-1.05 |

0.25-0.45 |

0.40-0.60 |

0.030 |

0.030 |

1.70-2.00 |

0.20-0.35 |

0.05-0.20 |

- |

Shell Hardenable, high wear resistance, high hardness |

Standards rolls of all diameters for cold rolling, back up rolls, straightening and work rolls |

|

PRODUCT |

DELIVERY CONDITION AND AVAILABLE DIMENSIONS |

|||

|

ROUND BAR |

COLD DRAWING |

CENTERLESS GROUND |

PEELED |

TURNED |

|

DIAMETER IN MM |

2.5-12.0 |

8.5-16 |

16-75 |

75-510 |

|

SQUARE |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

SIZE IN MM |

6X6-50X50 |

55X55-510X510 |

||

|

FLAT BAR |

HOT ROLLED BLACK |

FORGED BLOCK ALL SIDE MILLED |

||

|

THICK X WIDTH IN MM |

3-40 X 12-610 |

80-405 X 100-810 |

||

|

STEEL SHEETS |

COLD ROLLED |

HOT ROLLED |

||

|

THICK x WIDTH xLENGTH IN MM |

1.2-3.0X600-800MM-1700-2100MM |

3.10-10.00X600-800MM-1700-2100MM |

||

|

Disc |

100-610MM DIA X1.5-10MM THICK |

|||

Product detail pictures:

Related Product Guide:

We believe that prolonged expression partnership is really a result of top of the range, value added support, rich encounter and personal contact for OEM manufacturer Cold Rolled Steel Sheets - COLD WORK STEEL – Histar , The product will supply to all over the world, such as: Seattle, Oman, Irish, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.