High Quality Hot Work Tool Steel Round Bar 1.2344/Skd61/H13 - HOT WORK STEEL – Histar

High Quality Hot Work Tool Steel Round Bar 1.2344/Skd61/H13 - HOT WORK STEEL – Histar Detail:

Mainly HOT WORK STEEL Grade No. We Supplied:

| HISTAR |

GB(CHINA) |

DIN |

ASTM |

JIS |

| HSH 13 | 4Cr5MoSiV1 | 1.2344 | H13 | SKD61 |

| HSH11 | 4Cr5MoSiV | 1.2343 | H11 | SKD6 |

| HSH12 | 4Cr5MoWSiV | 1.2606 | H12 | SKD62 |

| HSH10 | 4Cr3Mo3SiV | 1.2365 | H10 | SKD7 |

| HSH21 | 3Cr2W8V | 1.2581 | H21 | SKD5 |

| HSH6 | 5CrNiMo | 1.2714 | L6 |

CHEMICAL COMPOSITION

|

HISTAR |

DIN |

ASTM |

CHEMICAL COMPOSITION |

PROPERTY |

APPLICATION |

||||||||

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

V |

W |

|||||

|

HSH13 |

1.2344 |

H13 |

0.35-0.42 |

0.80-1.20 |

0.25-0.50 |

0.030 |

0.030 |

4.80-5.50 |

1.20-1.50 |

0.85-1.15 |

- |

High hardenability, excellent wear resistance and hot toughness. has good thermal shock resistance, (ESR) H13 has greater homogeneity and an exceptionally fine structure, resulting in improved machinability, polishability and high temperature tensile strength. |

Pressure die casting tools, extrusion die, forging dies, hot shear blades, stamping dies, plastic molds, Hot work mandrels, ESR H13 is great for aluminium die-casting tools and plastic mold tools requiring a very high polish. |

|

HSH12 |

1.2606 |

H12 |

0.32-0.40 |

0.90-1.20 |

0.30-0.60 |

0.030 |

0.030 |

5.00-5.60 |

1.30-1.60 |

0.15-0.40 |

1.20-1.40 |

Excellent impact toughness. The tungsten content provides better temper resistance, deep-hardening, air-hardening steel that exhibits minimal size change during heat treatment. Good resistance to thermal fatigue cracking |

hot punches, die casting dies, forging dies, hot shear blades, hot gripper dies, and extrusion dies. |

|

YTR50 |

1.2343 |

H11 |

0.33-0.41 |

0.80-1.20 |

0.25-0.50 |

0.030 |

0.030 |

4.80-5.50 |

1.10-1.50 |

0.30-0.50 |

- |

High hardenability, excellent toughness, good resistance to thermal shock when water cooled in service, minimal size change during heat treatment. |

Recommended for hot tooling applications where maximum resistance to cracking is required. Hot punches, die casting dies, forging dies, hot shear blades, hot gripper dies, extrusion dies. |

|

HSH10 |

1.2365 |

H10 |

0.28-0.35 |

0.10-0.40 |

0.15-0.45 |

0.030 |

0.030 |

2.70-3.20 |

2.50-3.00 |

0.40-70 |

- |

Excellent resistance to softening at elevated temperature. very resistant to thermal fatigue cracking, and can be water cooled in service |

Heavy metal Die-casting tools, Piercing Mandrels, Hot punches, forging dies, hot shear blades |

|

HSH21 |

1.2581 |

H21 |

0.25-0.35 |

0.10-0.40 |

0.15-0.45 |

0.030 |

0.030 |

2.50-3.20 |

- |

0.30-0.50 |

8.50-9.50 |

Exhibits excellent resistance to softening at elevated temperature. Should not be water cooled in service unless the tool includes a continuous flow of internal water cooling. Thermal shock should be avoided |

Recommended for difficult hot work tooling applications such as brass extrusion, brass die casting dies, hot punches, forging die inserts. |

|

HSH6 |

1.2714 |

L6 |

0.50-0.60 |

0.10-0.40 |

0.60-0.90 |

0.030 |

0.030 |

0.80-1.20 |

0.35-0.55 |

0.05-0.15 |

Ni 1.50-1.80 |

High impact toughness and good resistance to softening at elevated temperature. good resistance to thermal shock and thermal fatigue cracking, small dimensional changes during hardening. |

Die forging, die casting, extrusion, glass processing,. Mandrels, Die holders |

Mainly Cold Work Tool Steel Grade No. we supplied:

|

PRODUCT |

DELIVERY CONDITION AND AVAILABLE DIMENSIONS |

|||

|

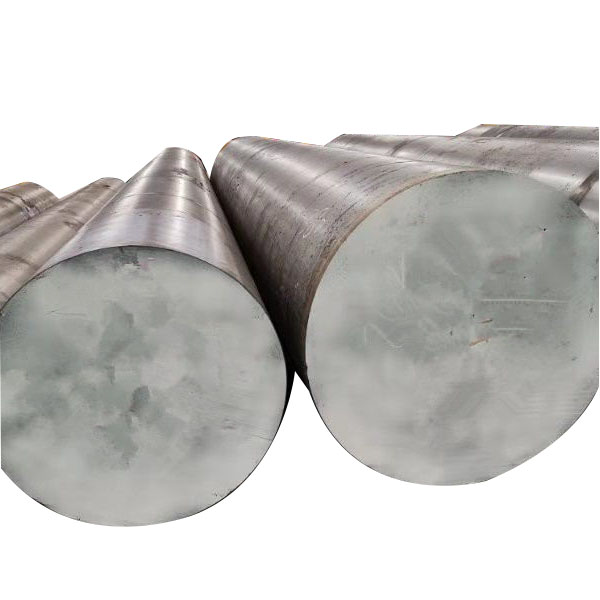

ROUND BAR |

COLD DRAWING |

CENTERLESS GROUND |

PEELED |

TURNED |

|

DIAMETER IN MM |

2.5-12.0 |

8.5-16 |

16-75 |

75-610 |

|

SQUARE |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

SIZE IN MM |

6X6-50X50 |

55X55-510X510 |

||

|

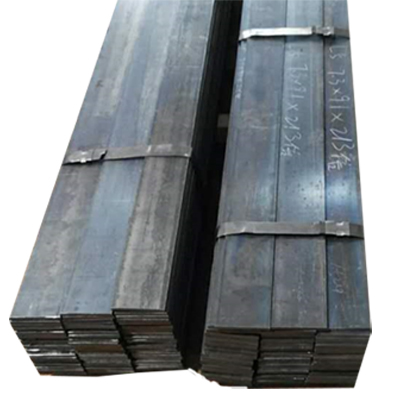

FLAT BAR |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

THICK X WIDTH IN MM |

3-40 X 12-610 |

80-405 X 100-810 |

||

|

DISC |

350-800MM DIA X80-400 THICK |

|||

Product detail pictures:

Related Product Guide:

We have now a hugely efficient team to deal with inquiries from buyers. Our goal is "100% client gratification by our solution high-quality, rate & our team service" and take pleasure in a great popularity among clients. With several factories, we will provide a wide assortment of High Quality Hot Work Tool Steel Round Bar 1.2344/Skd61/H13 - HOT WORK STEEL – Histar , The product will supply to all over the world, such as: New Orleans, Detroit, Doha, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.