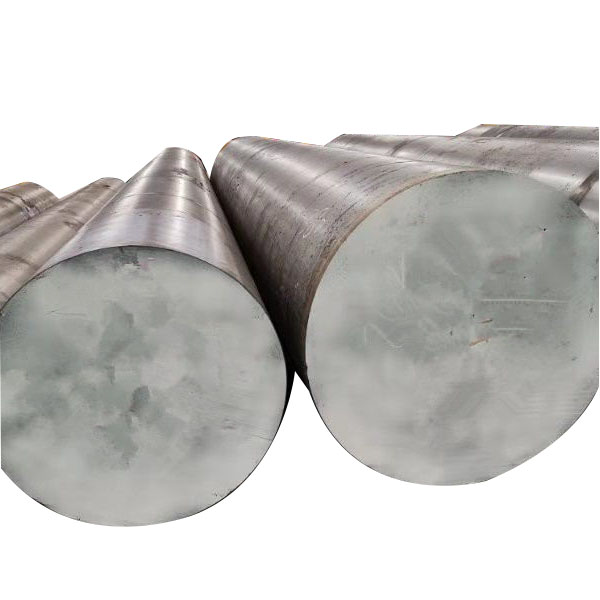

High definition Hot Work Steel Die Block - HOT WORK STEEL – Histar

High definition Hot Work Steel Die Block - HOT WORK STEEL – Histar Detail:

Mainly HOT WORK STEEL Grade No. We Supplied:

| HISTAR |

GB(CHINA) |

DIN |

ASTM |

JIS |

| HSH 13 | 4Cr5MoSiV1 | 1.2344 | H13 | SKD61 |

| HSH11 | 4Cr5MoSiV | 1.2343 | H11 | SKD6 |

| HSH12 | 4Cr5MoWSiV | 1.2606 | H12 | SKD62 |

| HSH10 | 4Cr3Mo3SiV | 1.2365 | H10 | SKD7 |

| HSH21 | 3Cr2W8V | 1.2581 | H21 | SKD5 |

| HSH6 | 5CrNiMo | 1.2714 | L6 |

CHEMICAL COMPOSITION

|

HISTAR |

DIN |

ASTM |

CHEMICAL COMPOSITION |

PROPERTY |

APPLICATION |

||||||||

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

V |

W |

|||||

|

HSH13 |

1.2344 |

H13 |

0.35-0.42 |

0.80-1.20 |

0.25-0.50 |

0.030 |

0.030 |

4.80-5.50 |

1.20-1.50 |

0.85-1.15 |

- |

High hardenability, excellent wear resistance and hot toughness. has good thermal shock resistance, (ESR) H13 has greater homogeneity and an exceptionally fine structure, resulting in improved machinability, polishability and high temperature tensile strength. |

Pressure die casting tools, extrusion die, forging dies, hot shear blades, stamping dies, plastic molds, Hot work mandrels, ESR H13 is great for aluminium die-casting tools and plastic mold tools requiring a very high polish. |

|

HSH12 |

1.2606 |

H12 |

0.32-0.40 |

0.90-1.20 |

0.30-0.60 |

0.030 |

0.030 |

5.00-5.60 |

1.30-1.60 |

0.15-0.40 |

1.20-1.40 |

Excellent impact toughness. The tungsten content provides better temper resistance, deep-hardening, air-hardening steel that exhibits minimal size change during heat treatment. Good resistance to thermal fatigue cracking |

hot punches, die casting dies, forging dies, hot shear blades, hot gripper dies, and extrusion dies. |

|

YTR50 |

1.2343 |

H11 |

0.33-0.41 |

0.80-1.20 |

0.25-0.50 |

0.030 |

0.030 |

4.80-5.50 |

1.10-1.50 |

0.30-0.50 |

- |

High hardenability, excellent toughness, good resistance to thermal shock when water cooled in service, minimal size change during heat treatment. |

Recommended for hot tooling applications where maximum resistance to cracking is required. Hot punches, die casting dies, forging dies, hot shear blades, hot gripper dies, extrusion dies. |

|

HSH10 |

1.2365 |

H10 |

0.28-0.35 |

0.10-0.40 |

0.15-0.45 |

0.030 |

0.030 |

2.70-3.20 |

2.50-3.00 |

0.40-70 |

- |

Excellent resistance to softening at elevated temperature. very resistant to thermal fatigue cracking, and can be water cooled in service |

Heavy metal Die-casting tools, Piercing Mandrels, Hot punches, forging dies, hot shear blades |

|

HSH21 |

1.2581 |

H21 |

0.25-0.35 |

0.10-0.40 |

0.15-0.45 |

0.030 |

0.030 |

2.50-3.20 |

- |

0.30-0.50 |

8.50-9.50 |

Exhibits excellent resistance to softening at elevated temperature. Should not be water cooled in service unless the tool includes a continuous flow of internal water cooling. Thermal shock should be avoided |

Recommended for difficult hot work tooling applications such as brass extrusion, brass die casting dies, hot punches, forging die inserts. |

|

HSH6 |

1.2714 |

L6 |

0.50-0.60 |

0.10-0.40 |

0.60-0.90 |

0.030 |

0.030 |

0.80-1.20 |

0.35-0.55 |

0.05-0.15 |

Ni 1.50-1.80 |

High impact toughness and good resistance to softening at elevated temperature. good resistance to thermal shock and thermal fatigue cracking, small dimensional changes during hardening. |

Die forging, die casting, extrusion, glass processing,. Mandrels, Die holders |

Mainly Cold Work Tool Steel Grade No. we supplied:

|

PRODUCT |

DELIVERY CONDITION AND AVAILABLE DIMENSIONS |

|||

|

ROUND BAR |

COLD DRAWING |

CENTERLESS GROUND |

PEELED |

TURNED |

|

DIAMETER IN MM |

2.5-12.0 |

8.5-16 |

16-75 |

75-610 |

|

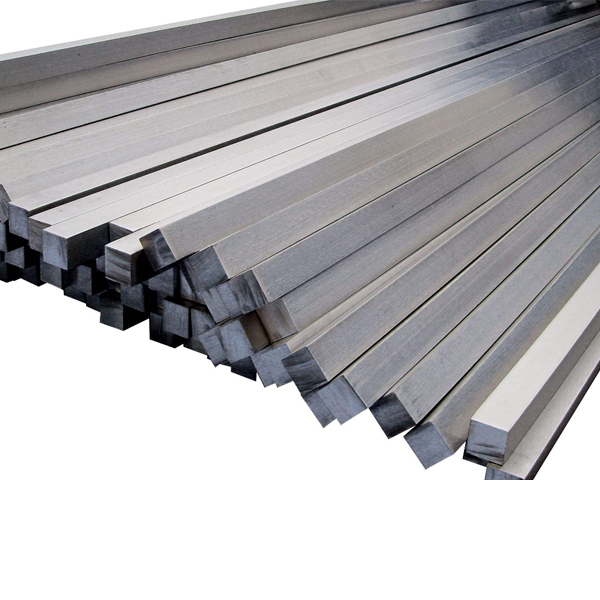

SQUARE |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

SIZE IN MM |

6X6-50X50 |

55X55-510X510 |

||

|

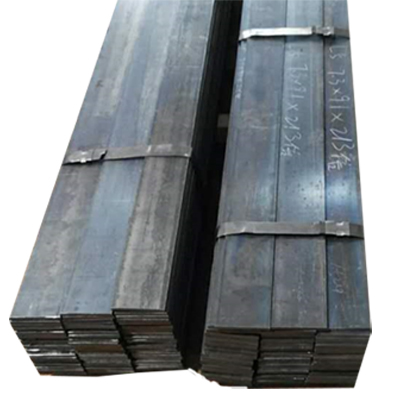

FLAT BAR |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

THICK X WIDTH IN MM |

3-40 X 12-610 |

80-405 X 100-810 |

||

|

DISC |

350-800MM DIA X80-400 THICK |

|||

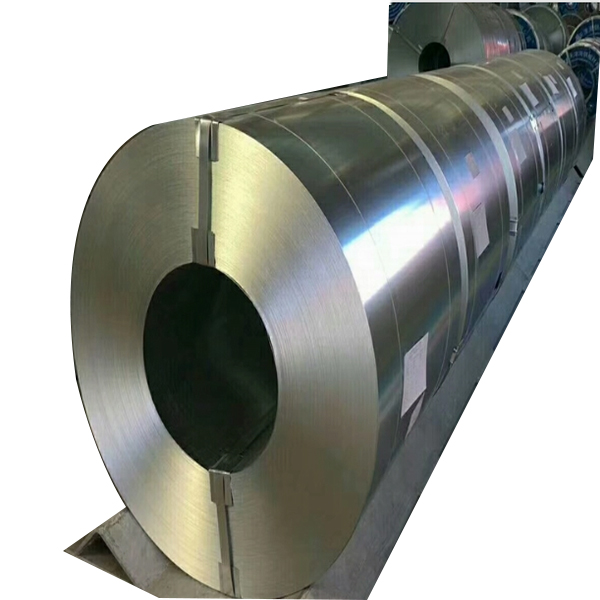

Product detail pictures:

Related Product Guide:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of High definition Hot Work Steel Die Block - HOT WORK STEEL – Histar , The product will supply to all over the world, such as: Hyderabad, Surabaya, United States, As a way to use the resource on the expanding info in international trade, we welcome prospects from everywhere on the web and offline. In spite on the high quality items we offer, effective and satisfying consultation service is supplied by our qualified after-sale service group. Item lists and detailed parameters and any other info weil be sent to you timely for the inquiries. So please make contact with us by sending us emails or call us when you've got any questions about our organization. ou could also get our address information from our site and come to our enterprise. We get a field survey of our merchandise. We are confident that we'll share mutual accomplishment and create solid co-operation relations with our companions within this market place. We're seeking forward for your inquiries.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.