Good Quality Cold Work Tool Steel - COLD WORK STEEL – Histar

Good Quality Cold Work Tool Steel - COLD WORK STEEL – Histar Detail:

Mainly Cold Work Steel Grade No. We Supplied:

| HISTAR |

DIN |

ASTM |

JIS |

| HSC 2 | 1.2379 | D2 | SKD11 |

| HSC3 | 1.2083 | D3 | SKD1 |

| HSC1 | 1.2510 | O1 | SKS93 |

| HSC7 | |||

| HSC8 | Bohler K340 | ||

| HSC9 | 1.2327 | Bohler K310 | |

| C28 | 1.2631 | A8 Mod. | |

| HSC50 | 1.2550 | S1 |

Size:

| HISTAR |

DIN |

ASTM |

CHEMICAL COMPOSITION |

PROPERTY |

APPLICATION |

||||||||

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

V |

W |

|||||

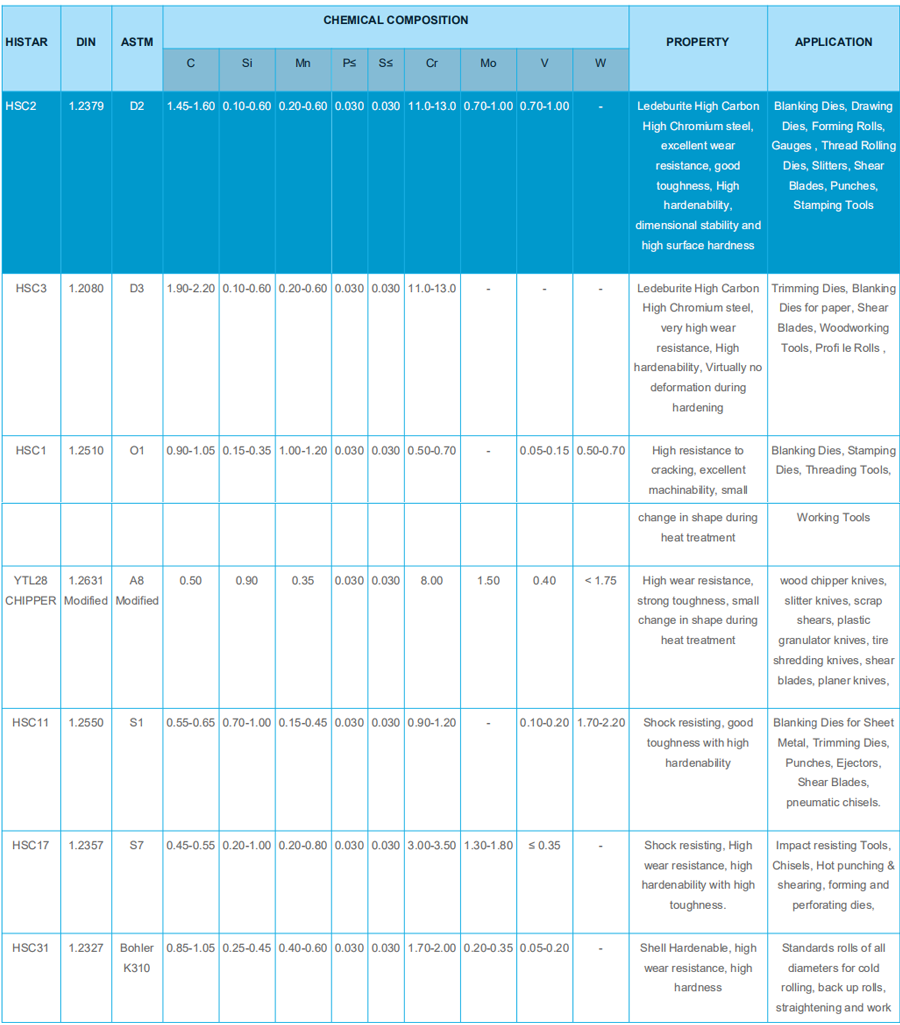

| HSC2 |

1.2379 |

D2 |

1.45-1.60 |

0.10-0.60 |

0.20-0.60 |

0.030 |

0.030 |

11.0-13.0 |

0.70-1.00 |

0.70-1.00 |

- |

Ledeburite High Carbon High Chromium steel, excellent wear resistance, good toughness, High hardenability, dimensional stability and high surface hardness |

Blanking Dies, Drawing Dies, Forming Rolls, Gauges , Thread Rolling Dies, Slitters, Shear Blades, Punches, Stamping Tools |

|

HSC3 |

1.2080 |

D3 |

1.90-2.20 |

0.10-0.60 |

0.20-0.60 |

0.030 |

0.030 |

11.0-13.0 |

- |

- |

- |

Ledeburite High Carbon High Chromium steel, very high wear resistance, High hardenability, Virtually no deformation during hardening |

Trimming Dies, Blanking Dies for paper, Shear Blades, Woodworking Tools, Profi le Rolls , |

|

HSC1 |

1.2510 |

O1 |

0.90-1.05 |

0.15-0.35 |

1.00-1.20 |

0.030 |

0.030 |

0.50-0.70 |

- |

0.05-0.15 |

0.50-0.70 |

High resistance to cracking, excellent machinability, small change in shape during heat treatment |

Blanking Dies, Stamping Dies, Threading Tools, Working Tools |

|

YTL28 CHIPPER |

1.2631 Modified |

A8 Modified |

0.50 |

0.90 |

0.35 |

0.030 |

0.030 |

8.00 |

1.50 |

0.40 |

< 1.75 |

High wear resistance, strong toughness, small change in shape during heat treatment |

wood chipper knives, slitter knives, scrap shears, plastic granulator knives, tire shredding knives, shear blades, planer knives, |

|

HSC11 |

1.2550 |

S1 |

0.55-0.65 |

0.70-1.00 |

0.15-0.45 |

0.030 |

0.030 |

0.90-1.20 |

- |

0.10-0.20 |

1.70-2.20 |

Shock resisting, good toughness with high hardenability |

Blanking Dies for Sheet Metal, Trimming Dies, Punches, Ejectors, Shear Blades, pneumatic chisels. |

|

HSC17 |

1.2357 |

S7 |

0.45-0.55 |

0.20-1.00 |

0.20-0.80 |

0.030 |

0.030 |

3.00-3.50 |

1.30-1.80 |

≤ 0.35 |

- |

Shock resisting, High wear resistance, high hardenability with high toughness. |

Impact resisting Tools, Chisels, Hot punching & shearing, forming and perforating dies, |

|

HSC31 |

1.2327 |

Bohler K310 |

0.85-1.05 |

0.25-0.45 |

0.40-0.60 |

0.030 |

0.030 |

1.70-2.00 |

0.20-0.35 |

0.05-0.20 |

- |

Shell Hardenable, high wear resistance, high hardness |

Standards rolls of all diameters for cold rolling, back up rolls, straightening and work rolls |

|

PRODUCT |

DELIVERY CONDITION AND AVAILABLE DIMENSIONS |

|||

|

ROUND BAR |

COLD DRAWING |

CENTERLESS GROUND |

PEELED |

TURNED |

|

DIAMETER IN MM |

2.5-12.0 |

8.5-16 |

16-75 |

75-510 |

|

SQUARE |

HOT ROLLED BLACK |

FORGED ALL SIDE MILLED |

||

|

SIZE IN MM |

6X6-50X50 |

55X55-510X510 |

||

|

FLAT BAR |

HOT ROLLED BLACK |

FORGED BLOCK ALL SIDE MILLED |

||

|

THICK X WIDTH IN MM |

3-40 X 12-610 |

80-405 X 100-810 |

||

|

STEEL SHEETS |

COLD ROLLED |

HOT ROLLED |

||

|

THICK x WIDTH xLENGTH IN MM |

1.2-3.0X600-800MM-1700-2100MM |

3.10-10.00X600-800MM-1700-2100MM |

||

|

Disc |

100-610MM DIA X1.5-10MM THICK |

|||

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for Good Quality Cold Work Tool Steel - COLD WORK STEEL – Histar , The product will supply to all over the world, such as: Venezuela, Switzerland, Iran, We also have good cooperation relationships with many good manufacturers so that we can provide almost all of auto parts and after-sales service with high quality standard,lower price level and warmly service to meet demands of customers from different fields and different area.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!