2018 Good Quality Plastic Mold Steel Dealer - PLASTIC MOULD STEEL – Histar

2018 Good Quality Plastic Mold Steel Dealer - PLASTIC MOULD STEEL – Histar Detail:

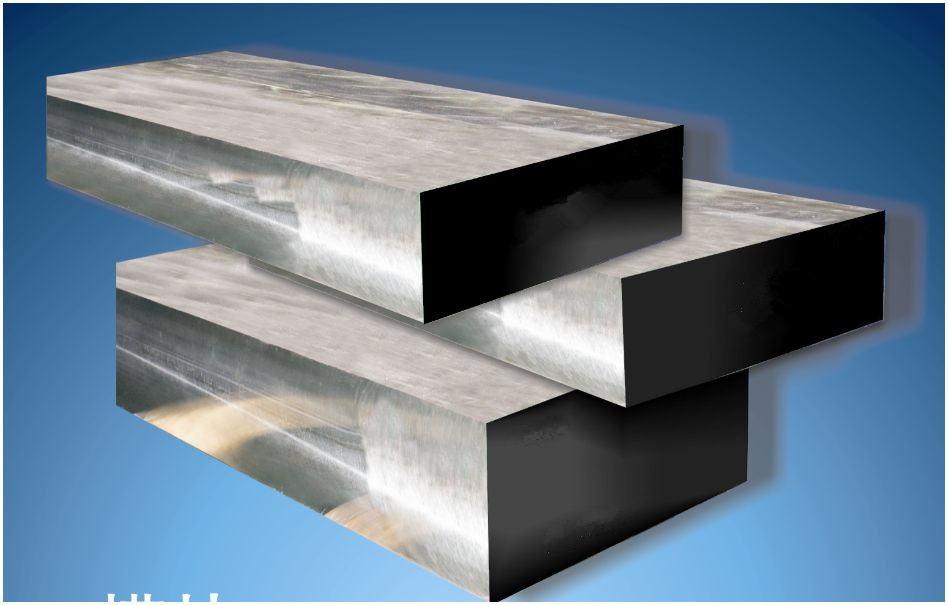

PLASTIC MOULD STEEL DIE BLOCK

Property:

- Wear resistance

- Polishability

- Machinability

- Toughness and hardness

- Thermal conductivity

Application:

MOULD STEELS typically have lower carbon content—0.36 to 0.40% and chromium and nickel are the main alloying elements. These characteristics allow these materials to be polished to an extremely high finish.

Mainly Plastic Mould Steel Grade No. we supplied:

| HISTAR |

DIN |

ASTM |

JIS |

| HSM83 | 1.2083 | 420 | SUS420 |

| HSM 16 | 1.2316 | ||

| HSM11 | 1.2311 | P20 | |

| HSM38 | 1.2738 | P20+Ni |

CHEMICAL COMPOSITION

|

HISTAR |

DIN |

ASTM |

CHEMICAL COMPOSITION |

PROPERTY |

APPLICATION |

||||||||

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

V |

Ni |

|||||

|

HSM83 |

1.2083 |

|

0.36-0.42 |

≤ 1.0 |

≤ 1.0 |

0.030 |

0.030 |

12.50-14-50 |

|

≤ 0.20 |

(0.60) |

supreme polishability, good corrosion resistance, and good wear resistance. material of choice for the manufacture of plastic molding tools that require the highest lens-quality polished fi nishes |

molds for compact disks (CDs), medical laboratory equipment, optical lenses, and other components, which require critical surface fi nishes. |

|

HSM16 |

1.2316 |

|

0.33-0.45 |

≤ 1.0 |

≤ 1.50 |

0.030 |

0.030 |

15.5-17.5 |

0.80-1.30 |

- |

≤ 1.00 |

high cleanliness/homogeneity, powerful in resistant to rust and corrosion, good polishability, usually supplied in quenched and tempered condition with a working hardness of approximately 300 HB. |

For Mould with strong corrupt resisting used for camera lens, Dies for pressing chemically aggressive compounds |

|

HSM11 |

1.2311 |

P20 |

0.35-0.45 |

0.20-0.40 |

1.30-1.60 |

0.030 |

0.030 |

1.80-2.10 |

0.15-0.25 |

- |

- |

Prehardened plastic mold steel, hardness in as-supplied condition 280-320 HB that is characterized by good toughness at moderate strength level good polishability and etching ability, adequate corrosion resistance, and cost efficient machining properties. |

Plastic molds, Mold frames for plastic molds and pressure casting dies, Heated recipient casings and tooling and for die casting dies for zinc. |

|

HSM38 |

1.2738 |

P20+Ni |

0.35-0.45 |

0.20-0.40 |

1.30-1.60 |

0.030 |

0.030 |

1.80-2.10 |

0.15-0.35 |

- |

0.90-1.20 |

Prehardened plastic mold steel, hardness in as-supplied condition 280-320 HB The high nickel content (1%) is specially adapted to ensure a perfect homogeneity of structure and hardness through thickness even for very thick blocks, good polishability, adequate corrosion resistance, good machinability. |

Large size Plastic Injection and blow moulding dies, mould frame for pressure casting dies, Heated recipient casings |

Size:

|

PRODUCT |

DELIVERY CONDITION AND AVAILABLE DIMENSIONS |

|||

|

ROUND BAR |

COLD DRAWING |

CENTERLESS GROUND |

PEELED |

TURNED |

|

DIAMETER IN MM |

16-75 |

75-250 |

||

|

FLAT BAR |

HOT ROLLED BLACK |

FORGED BLOCK ALL SIDE MILLED |

||

|

THICK X WIDTH IN MM |

15X80-150X1000 |

80X500-200X1000 |

||

Product detail pictures:

Related Product Guide:

No matter new customer or outdated client, We believe in extensive phrase and trusted relationship for 2018 Good Quality Plastic Mold Steel Dealer - PLASTIC MOULD STEEL – Histar , The product will supply to all over the world, such as: Somalia, Portugal, Switzerland, Company name, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by ISO quality management standard strictly, creating top-ranking company by spirit of progress-marking honesty and optimism.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.